Discover the news of the industrial group expert in the protection of sensitive and hazardous materials, as well as the list of trade shows and events in which Tournaire participates.

Aluminum at the Service of Sensitive Materials: The Evolution of Technical Packaging

The Evolution of Technical Packaging

Discover the fascinating history of Tournaire, a pioneer in technical packaging for nearly two centuries. Embark on an industrial adventure where innovation and adaptation are the key words. From the era of copper to the advent of aluminum, a preferred material for sensitive substances, Tournaire has anticipated its clients’ needs by offering packaging solutions combining lightness, flexibility, and durability.

With particular attention to safety and performance, the company has revolutionized the transport of hazardous and precious materials. The OMNI PLUS range embodies this excellence, offering recyclable aluminum packaging that meets the strictest environmental standards. Be inspired by this industrial epic and discover how Tournaire continues to push the boundaries of innovation for a more sustainable future.

History of a Pioneer

The Copper Era

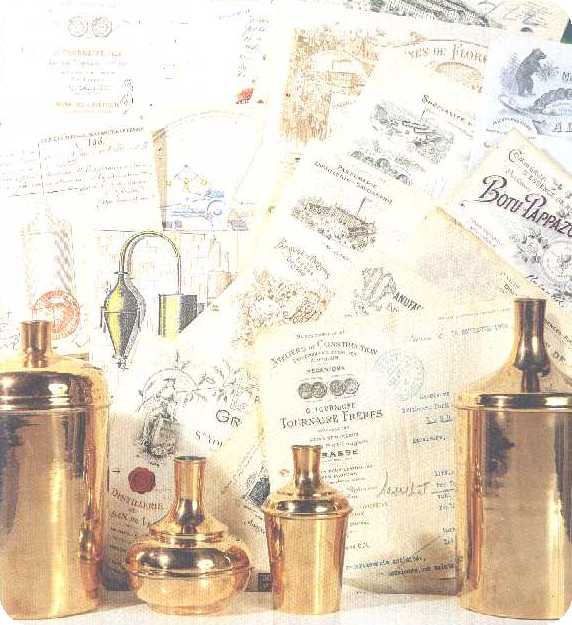

As the bustling trading city of Grasse added perfumes and flower extracts to its production of olive oil, leather, and gloves, a new guild emerged: the distillers. This emergence led to the development of coppersmiths who had to expand their expertise to the making of stills. In this context, in 1833, Joseph Tournaire, the son and grandson of millers, set up a 40m² workshop at Place de la Roque. By the end of the 19th century, the perfume industry required no less than six coppersmith workshops in Grasse.

Nearly two hundred years ago, Tournaire was the sixth coppersmith shop in Grasse, but the company stood out as a copper specialist equipment supplier during the great industrializations. Perfume companies, in full expansion, transformed more and more raw materials. They sought to eliminate the effects of seasonality. The goal was to continue transforming materials during the season but to store them throughout the year and export them worldwide.

Coppersmiths, experts in metal transformation, understood well the constraints associated with sensitive materials. Tournaire, a copper specialist, then offered suitable packaging solutions. The copper estagnon was born. Perfume companies found in Tournaire a partner capable of meeting their specific needs.

However, aware that welds were the weak point of copper tanks, Tournaire innovated by aiming to reduce the number of welds in its estagnons. Through perseverance, Tournaire, a technical pioneer, reduced the number of welds in its estagnon solutions from three to one. Thanks to this technical innovation, the risk of cracks and leaks was instantly reduced, ensuring better preservation of materials.

Despite its qualities of flexibility, lightness, and solidity, copper has drawbacks: it oxidizes easily, requiring regular tinning, and its cost is relatively high. These constraints led Tournaire to seek more economical and sustainable alternatives.

The Advent of Aluminum

Bauxite was discovered by chemist Pierre Berthier in 1821 in the commune of Baux-de-Provence (Bouches-du-Rhône) while he was searching for iron ore on behalf of Lyon industrialists. He named the discovery “alumina earth from Baux.” This name was transformed into “beauxite” by Armand Dufrénoy in 1847, and then into “bauxite” by Henry Sainte-Claire Deville in 1861. The world’s first industrial aluminum production site using bauxite was established in Salindres in the Gard as early as 1860.

In the 1920s and 1930s, Tournaire explored new alternatives to copper. Taking advantage of its geographical proximity to bauxite sources, Tournaire became interested early on in the benefits of aluminum for packaging its clients’ most sensitive materials.

Staying true to its original goal, Tournaire adhered to its principles of securing sensitive materials and reducing the number of welds. Thus, the company saw aluminum as an ideal solution. Aluminum, indeed, allowed the number of welds to be reduced to zero, eradicating the risk of leaks due to tears or cracks. This advancement marked the beginning of the modern era of packaging, enabling hundreds of thousands of kilos of hazardous, sensitive, rare, expensive, and fragile materials to travel safely around the world.

In addition to its intrinsic advantages of lightness and flexibility, aluminum offers remarkable resistance to corrosion and chemical neutrality, making it ideal for contact with a wide range of molecules. These properties enable the development of high-performance packaging solutions tailored to the growing demands of the perfume industry and other sensitive sectors such as pharmaceuticals. The adoption of this material also improves manufacturing efficiency. It is indeed easier to transform and handle than copper, reducing production costs while increasing the quality and reliability of packaging. This innovation strengthens the position of technical packaging manufacturers capable of meeting their clients’ most demanding needs.

Today, thanks to its innovations and expertise, Tournaire continues to play a pioneering role in the field of technical packaging solutions. Its innovations demonstrate Tournaire’s ability to anticipate its clients’ needs and offer solutions adapted to contemporary industry challenges.

Aluminum, the Obvious Choice

Properties of Aluminum

Aluminum has established itself as the number one choice for high-performance monobloc packaging at Tournaire, and not without reason. Its versatility, mechanical properties, and environmental benefits make it a material of choice for various applications, particularly in the health, chemical, food, and perfume sectors. Here is an in-depth exploration of the many advantages of aluminum in this context.

Ductility and Flexibility

The ductility of aluminum, its ability to be stretched and shaped without breaking, is a major advantage. Aluminum can be described as a “soft metal,” which presents two significant benefits:

Good formability: Aluminum can be transformed into complex designs from a single piece of metal. This ability to create monobloc packaging means that timbales and containers can be produced with mastered clippings, threads, and rollings, ensuring safe industrial manufacturing.

Shock absorption: The flexibility of aluminum allows cans to withstand shocks without tearing or puncturing. This enables them to easily pass drop tests required by hazardous materials regulations, simulating real transport and use conditions. This shock resistance is crucial to ensure the safety and integrity of packaged products, especially hazardous materials.

Ultimate Barrier Properties

The barrier properties of aluminum make it a top choice for packaging intended for health or chemical products, food, and perfumes. Aluminum naturally resists corrosion, ensuring the protection and quality of packaged products over a long period. In addition to protecting against light and moisture, it prevents the penetration of odors and aromas, essential for maintaining the freshness and flavor of the most sensitive molecules.

Tournaire’s packaging can also be varnished to maximize compatibility between the container and the content, particularly for very aggressive contents.

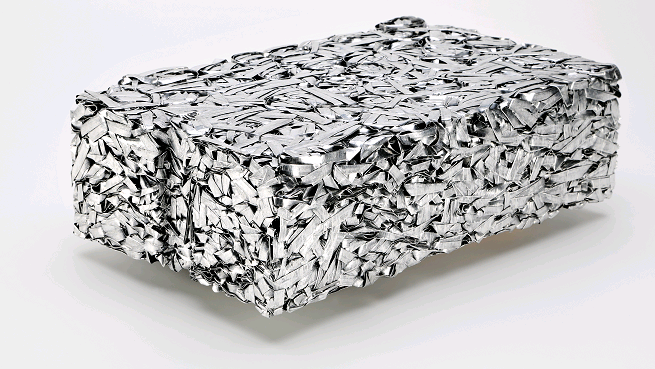

Recyclability

Aluminum is infinitely recyclable without losing its mechanical properties, making it an extremely durable material. Recycling aluminum saves up to 95% of energy resources compared to the production of primary aluminum. Moreover, about 75% of the aluminum produced since the beginning of the 20th century is still in circulation today, demonstrating the durability and longevity of this material.

Thus, the creation of primary aluminum today can be considered the creation of a low-energy resource for the future. The use of recycled aluminum not only reduces energy consumption but also greenhouse gas emissions, contributing to a cleaner and more sustainable environment.

Lightweight

One of aluminum’s main advantages is its lightness. This factor is crucial for the transport of goods as it significantly reduces transportation costs. Indeed, most transportation costs are often invested in the material being transported rather than its container. Aluminum’s lightness thus helps reduce these costs and, consequently, the carbon footprint associated with transportation.

Safety and Neutrality

Aluminum is non-toxic and inert, making it safe for food and pharmaceutical packaging. It does not react with food products, ensuring that it does not alter the taste or smell of packaged food. This chemical inertia is crucial to ensure food safety and product quality over the long term.

Conclusion

In conclusion, aluminum stands out as the material of choice for high-performance monobloc packaging. Its lightness, ductility, recyclability, barrier properties, and safety make it an ideal material for a variety of industrial applications. Using aluminum not only reduces costs and carbon footprint but also ensures the quality and safety of packaged products. By opting for aluminum packaging, companies can meet the growing demands for sustainability and performance while remaining competitive in the market.

Regulations and the Future

Aluminum and the Future of Packaging in a Regulatory Framework

In the future, aluminum will remain a material of choice for packaging due to its unique properties and its ability to adapt to growing environmental requirements. Regulations play a crucial role in this transition towards more virtuous practices. In particular, the AGEC law (Anti-Waste for a Circular Economy) represents a major turning point in France for promoting a circular economy and reducing waste. Adopted and promulgated on February 10, 2020, this legislation proposes a set of measures aimed at improving waste management, encouraging recycling, and promoting the reuse and repair of products.

Objectives of the AGEC Law

The AGEC law revolves around several main objectives aimed at transforming our current economic model:

- Reduce waste: The law implements measures to reduce waste production. This includes limiting single-use products and encouraging more sustainable product design.

- Promote reuse and repair: Emphasis is placed on extending product lifespans through reuse and repair practices. This means that products should be designed to be used multiple times or reconditioned for new use.

- Increase recycling: The law aims to improve recycling rates by developing more efficient recycling channels and strengthening sorting obligations. This involves better separation of materials and more efficient management of recyclable waste.

These objectives are summarized by the 3 R’s: Reduce, Reuse, and Recycle. Packaging, particularly that of Tournaire, is designed to meet these imperatives.

Technical Packaging and the 3 R’s

Reduce

Packaging must have a minimal ecological footprint. This means reducing packaging weight to decrease transportation costs and environmental impact. Moreover, it is crucial to minimize the number of materials used in packaging. Multilayers, overwrapping, and complex assemblies should be avoided. The goal is to create simple and efficient packaging that requires fewer resources for its manufacture and recycling.

Reuse

Packaging must be designed for maximum reuse. This means they must be robust and withstand several cycles of use without degrading. The durability of materials is essential to ensure that packaging can be reused many times before becoming waste. This approach extends the lifespan of packaging and reduces the demand for new materials.

Recycle

Packaging must be recyclable, ideally made from a single material or easily separable materials.

The integration of recycled materials into the production of new packaging is also a priority. By studying the impact of integrating recycled aluminum, Tournaire is investing to contribute to reducing the extraction of raw materials and preserving natural resources.

Recycling is a major issue, but there are technical barriers to ensure the mechanical performance of packaging and thus ensure the physical protection of materials. Tournaire must also ensure the maintenance of the chemical integrity of client products. Thus, the chemical neutrality of the packaging is a major issue in this evolution.

Towards a Sustainable and Responsible Future

The AGEC law represents a significant step towards a more circular and sustainable economy in France. By emphasizing waste reduction, reuse, and recycling, this legislation encourages businesses and consumers to adopt more responsible practices.

Aluminum packaging, such as that produced by Tournaire, is particularly well-suited to these new requirements due to its lightness, durability, and recyclability. By adopting more sustainable economic models and complying with new regulations, companies can not only reduce their environmental impact but also meet the growing consumer expectations for sustainability.

Tournaire’s Response

The technical constraints associated with packaging hazardous materials being more rigorous, environmental requirements are sometimes relaxed. It may be more prudent to opt for packaging with a less controlled carbon footprint, but which ensures better protection of the environment against the hazardous materials packaged, rather than non-polluting packaging that could pose a risk of environmental contamination by these substances.

Although requirements may be slightly more flexible, the main goal remains to protect both the environment from hazardous materials and these materials from the environment, while controlling the carbon footprint of the packaging solution. Tournaire ensures that its packaging, approved for the transport of hazardous materials, meets essential safety standards while controlling the environmental impact of its solutions, as evidenced by the innovative OMNI PLUS range.

OMNI PLUS

Presentation of OMNI PLUS

The OMNI PLUS range from Tournaire embodies the excellence of sustainable and high-performance packaging. Carefully designed, this range uses pure aluminum, thus meeting modern requirements for weight reduction and material minimization. Thanks to the flexibility of aluminum, OMNI PLUS eliminates the need for overwrapping in most cases, reducing the ecological cost of manufacturing. Thus, with this range, Tournaire aligns with the AGEC law and the 3 R’s.

OMNI PLUS, true to its ecological commitment, continues to reduce its weight while maintaining its robustness, notably with a 7% reduction in the total weight of the most sold solution compared to its Système Plus equivalent. Aluminum, the central material of this range, allows energy-efficient transformation, thus minimizing the ecological footprint of production. Moreover, the reduction in the number of components used in the packaging solution and their easy separation also simplifies the recycling process, contributing to an efficient circular economy.

The design of OMNI PLUS cans also facilitates their recycling. The separation between plastic and aluminum components optimizes the recycling process, thus reducing environmental costs. This approach ensures that each material can be treated optimally, maximizing recycling efficiency.

Furthermore, by investing in solutions that integrate recycled materials, Tournaire demonstrates its commitment to reducing raw material extraction and preserving natural resources while facilitating the recycling of already extracted resources.

The OMNI PLUS range from Tournaire represents an innovative and sustainable response to the challenges posed by technical packaging. By reducing packaging weight, enabling reuse, and facilitating recycling, Tournaire strives not only to protect the environment but also to meet the strict safety and performance requirements of its clients. This pioneering and proactive approach places Tournaire at the forefront of modern packaging solutions, proving its unwavering commitment to excellence and sustainability.

Tournaire continues to anticipate its clients’ future needs, offering solutions that combine safety, performance, and environmental respect. The OMNI PLUS range is a testament to this vision, marking a significant milestone in the history of industrial technical packaging and confirming Tournaire as a leading player in this field.

Conclusion

Our History

In conclusion, the history of Tournaire, from the copper era to the advent of aluminum, demonstrates the company’s capacity for innovation and adaptation. Tournaire has met the challenges of each era by adopting increasingly efficient and environmentally friendly materials and processes.

Today, thanks to the OMNI PLUS range, Tournaire continues to lead the way in sustainable and high-performance packaging. Aluminum, with its lightness, flexibility, and infinite recyclability, allows Tournaire to offer packaging solutions that not only reduce the carbon footprint but also ensure optimal safety for the most sensitive and hazardous materials.

Our Commitment

Tournaire’s commitment to innovation and sustainability is also reflected in its compliance with regulations such as the AGEC law and its anticipation of future regulations such as PPWR and Pfas, for example. Tournaire is fully engaged in a circular economy approach.

The future of technical packaging lies in solutions that combine performance and environmental respect. Tournaire, with its OMNI PLUS range, is at the forefront of this evolution, bringing packaging for the most sensitive materials closer to carbon neutrality.

By continuing to innovate and adapt to its clients’ needs, Tournaire proves that it is possible to reconcile technical excellence and environmental responsibility. It is this pioneering vision that allows Tournaire to remain a key player in packaging solutions, anticipating the challenges of tomorrow while meeting the demands of today.

Appendices

Glossary: Key Terms

Aluminum: A lightweight metal resistant to corrosion, offering excellent sealing and container integrity. It is infinitely recyclable without losing its mechanical properties.

Coppersmith: An artisan specialized in working with copper and metals to make utensils, stills, and other containers.

Transport

Estagnon: A metal container, initially made of copper, used to store and transport essential oils and other sensitive materials.

Recyclability: The ability of a material to be reused after processing to make new products, thus reducing the carbon footprint and use of natural resources.

Barrier properties of packaging: The ability of a material to protect its content from light, moisture, odors, and aromas, thus preserving the quality and freshness of packaged products.

Food safety: Ensuring that packaging materials do not chemically interact with food, maintaining its taste, smell, and safety.

AGEC Law (Anti-Waste for a Circular Economy): French legislation aimed at promoting a circular economy, reducing waste, and encouraging recycling and product reuse.

Circular economy: An economic system aimed at minimizing waste and maximizing reuse, repair, recycling, and the durability of products and materials.

UN Number (United Nations Organization): A unique identification code assigned to each hazardous substance, defining its nature and associated risks.

Transport of hazardous materials: A set of rules and practices to ensure safety when moving substances that may pose risks to health, safety, or the environment.

ISO Certification: An international standard indicating that an organization meets quality and environmental management requirements.

Cleanliness (Three levels at Tournaire):

- Microbiological cleanliness: Monitoring and control of living contaminants to ensure sterility.

- Chemical cleanliness: Monitoring levels of chemical pollutants to maintain unmatched chemical cleanliness.

- Particulate cleanliness: Monitoring significant particle sizes to ensure content purity.

Sealing: The ability of packaging to prevent leaks or exposure of its content.

Pressure resistance: The ability of packaging to withstand internal or external pressures without failure.

Compliance and Performance: For Tournaire, regulatory compliance is considered a minimum. The company goes beyond by focusing on performance, taking additional safety margins to provide peace of mind to clients. Tournaire also anticipates future stricter standards, ensuring that its clients remain compliant and ahead of regulatory requirements.

Inviolability and anti-counterfeiting: Characteristics of packaging designed to prevent unauthorized opening or tampering with the content.

Environment

Sustainability: The practice of using resources in a way that does not compromise the needs of future generations.

Social responsibility: The commitment of a company to act ethically and contribute to economic development while improving the quality of life for employees and society.

Life cycle analysis: An assessment of the environmental impact of a product throughout its life cycle, from production to disposal.

References and Sources: For Further Reading

Sources

- Aluminum Recycling Factsheet

- Properties of Aluminum from studies in metallurgy and materials engineering.

- Certified packaging for the transport of hazardous materials (TMD)

- Infinitely Recyclable

These sources provide a comprehensive understanding of aluminum’s properties, hazardous material transport regulations, and sustainable practices adopted by Tournaire to meet environmental and industrial requirements.

Want to Know More? Contact Tournaire Experts

Our guide has offered you an in-depth overview of hazardous materials transport and Tournaire’s excellence in providing secure and innovative packaging solutions. If you wish to explore in more detail how our products and services can meet your specific needs, we are here to help.

Our experts are at your disposal for a personalized consultation.

Visit our contact form to let us know your needs and questions. A member of our team will respond as soon as possible to provide expert advice tailored to your industrial context.

Tournaire is committed to providing not only high-quality products but also support and expertise that makes a difference. Contact us today to move your project forward with a partner you can count on.