Discover the news of the industrial group expert in the protection of sensitive and hazardous materials, as well as the list of trade shows and events in which Tournaire participates.

CHOOSE THE MOST SUITABLE PACKAGING TO TRANSPORT YOUR DANGEROUS GOODS

Whether you are a professional in the chemical, pharmaceutical or any other sector that has sensitive products, the transporting of dangerous goods and its packaging is a major and specific aspect of your logistics, which is often multimodal and globalised. Strategic decisions are required that take into account, from the outset, the associated constraints and regulations for each stage and for each mode of transport in the chosen supply chain. In addition, the primary packaging of sensitive products and the appropriate overpackaging that will allow the transporting of dangerous materials without risk must be defined from the launch of the product or project, whether such risks are:

- physical: leakage, major degradation,

- commercial: appearance of the packaging or product altered during transport,

- legal: customs or other services of the States crossed blocking the goods,

- logistics: a forwarding agent, carrier, pilot or captain refusing to take the goods on board.

You also need to choose certified, trusted, partners for the packaging and transporting of dangerous materials.

01. WHAT ARE THE CONSTRAINTS ON THE PACKAGING OF SENSITIVE PRODUCTS DURING TRANSPORT?

03. WHICH PARTNER SHOULD YOU CHOOSE TO TRANSPORT OF YOUR DANGEROUS MATERIALS?

WHAT ARE THE CONSTRAINTS ON THE PACKAGING OF SENSITIVE PRODUCTS DURING TRANSPORT?

International regulations consider any products that may constitute a risk for the population, the environment or property to be dangerous materials. Dangerous materials are classified into 13 categories and sub-categories:

- 1. Explosive substances and items

- 2. Compressed, liquefied or dissolved pressurized gases

- 3. Flammable liquids

- 4.1. Flammable solids

- 4.2. Spontaneously combustible substances

- 4.3. Substances that, when in contact with water, emit flammable gases

- 5.1. Oxidising substances

- 5.2. Organic peroxides

- 6.1. Toxic substances

- 6.2. Infectious substances

- 7. Radioactive materials

- 8. Corrosive materials

- 9. Miscellaneous dangerous materials and objects

On a global scale, the United Nations (ONU) ensures the consistency of the various TGD (Transport of Dangerous Goods). regulations. It has published the famous ” orange book ” that lists each dangerous material under a unique code that regulates the transport constraints and the choice of dangerous material packaging. In Europe, EC Directive 2008/68 of the European Parliament and of the Council on the inland transport of dangerous goods makes it compulsory to apply the international agreements on TDG by road (ADR) ), rail (RID) and sea (ADN).

On a global scale, the United Nations (ONU) ensures the consistency of the various TGD (Transport of Dangerous Goods). regulations. It has published the famous ” orange book ” that lists each dangerous material under a unique code that regulates the transport constraints and the choice of dangerous material packaging. In Europe, EC Directive 2008/68 of the European Parliament and of the Council on the inland transport of dangerous goods makes it compulsory to apply the international agreements on TDG by road (ADR) ), rail (RID) and sea (ADN).

For each product that may contain several components and, therefore, several material codes, all of the constraints apply, or the highest, both for the choice of packaging for the sensitive material and for the transport methods.

It should be remembered that even if the different modes of transport are harmonised under the UN regulations, each mode of transport and even each country has enacted its own rules:

- by road, it is the ADR (Agreement on Dangerous Goods by Road) that prevails in Europe. In the USA, it is the DOT (Department of Transportation) that regulates road transport.

- by plane, you must comply with the rules defined by the International Air Transport Association (IATA), which are among the most rigorous.

- for the sea, it is the IMDG(International Maritime Dangerous Goods) or the ADN (European Agreement concerning the International Carriage of Dangerous Goods by Inland Waterways) that lays down the specific rules for such transport.

- Lastly, for rail, it is the RID (Regulations concerning the International Carriage of Dangerous Goods by Rail) that define the rules of transport.

These different regulations impose various constraints on the packaging of sensitive materials during transport depending on the situation: appointment of a Safety Advisor, labelling and marking of packaging and overpacks, documentation, limited quantities, etc, and they also define rules for the choice and approval of packaging.

HOW TO CHOOSE OR DESIGN AND OBTAIN APPROVED PACKAGING FOR THE TRANSPORTING OF YOUR DANGEROUS MATERIALS?

Initially, it is often the flow of goods, the type of packaged product and the end use that will determine the choice of packaging for dangerous materials and its overpackaging. Bulk chemicals will use 1,000 L Intermediate Bulk Containers (IBCs) (‘unitary’ packaging within the meaning of the TDG – Transport of Dangerous Goods), where finished products will be packaged in small metal bottles, for example, then in boxes (so-called ‘combination’ packaging), then grouped on pallets for transport. For many chemical and pharmaceutical industries, the TDG constraint is an integral part of the packaging specifications that it is evolving and requires internal expertise and/or very reliable, specialised, partners.

Once the types of packaging and overpackaging have been selected, the product to be transported must be examined and, for each of its components, the UN code must be determined that will ultimately define the associated constraints, in particular the dangerousness group for the packaged product:

- Group I for very dangerous materials,

- Group II for moderately dangerous materials,

- Group III for low danger materials.

Depending on the danger group and the type of approval in question – unitary or combination – a UN-approved primary packaging or grouping box must have successfully passed a series of tests at an approved national laboratory: leakproofness, drop, pressure resistance, stacking, etc.

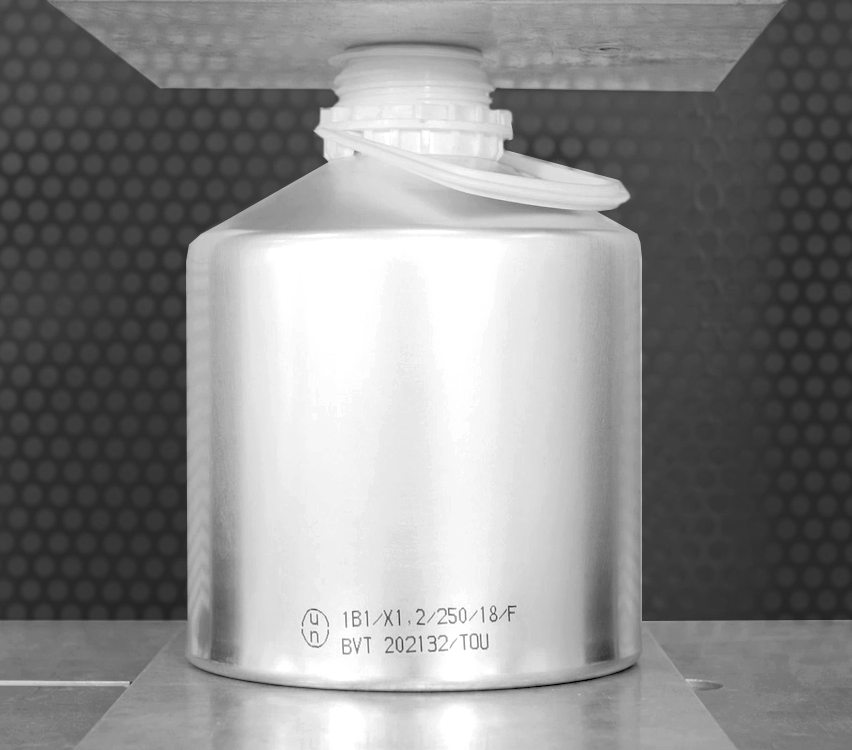

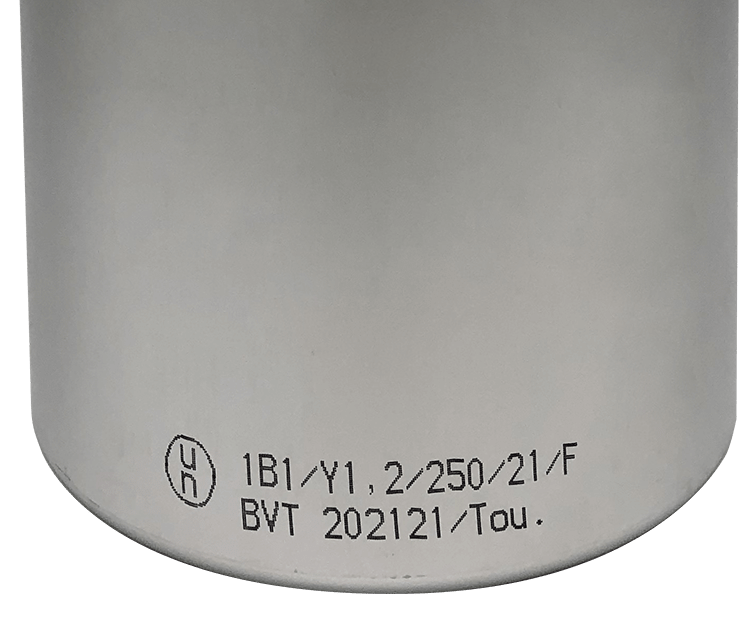

In France, the principal, approved, laboratories are the BVT (Bureau de Vérifications Techniques – Technical check office), LNE (Laboratoire National de métrologie et d’Essais – National Metrology and Testing Laboratory), LEREM (Laboratoire d’Etudes et de Recherches des Emballages Métalliques – Metal Packaging Studies and Research Laboratory)). There is also the BAM in Germany for example.

These laboratories, after having applied and validated the various regulatory tests, assign a UN number that must appear on the grouped packaging (‘combination’ approval) or on each packaging for dangerous materials (‘unitary’ approval). The UN number includes or codifies the following information:

- the type of packaging (eg, ‘1B1’ is aluminium packaging with a partial opening),

- the danger group (eg, ‘X’ for groups I, II or III, ‘Y’ for groups II and III, ‘Z’ for group III only),

- the maximum density or mass of the approved product,

- test pressure in kPA,

- the year of manufacture,

- the country of manufacture,

- the identification of the laboratory that carried out the tests and the report number,

- the identification of the manufacturer.

WHICH PARTNER SHOULD YOU CHOOSE TO TRANSPORT OF YOUR DANGEROUS MATERIALS?

This complex sector requires internal or external partners who are fully conversant with the various aspects of the transporting of dangerous materials:

- technics – specific to each type of packaging, overpackaging, transported products,

- regulations – UN, ADR, etc, and their updates,

- logistics.

As far as suppliers of packaging for dangerous materialsare concerned, you can use a manufacturer or a distributor, depending on your needs.

The distributor will direct you to various ranges or types of approved packaging for sensitive products that it has in stock and will give you the Certificate of Approval for the packaging sold, a document that guarantees the validity and conformity of the packaging that you use.

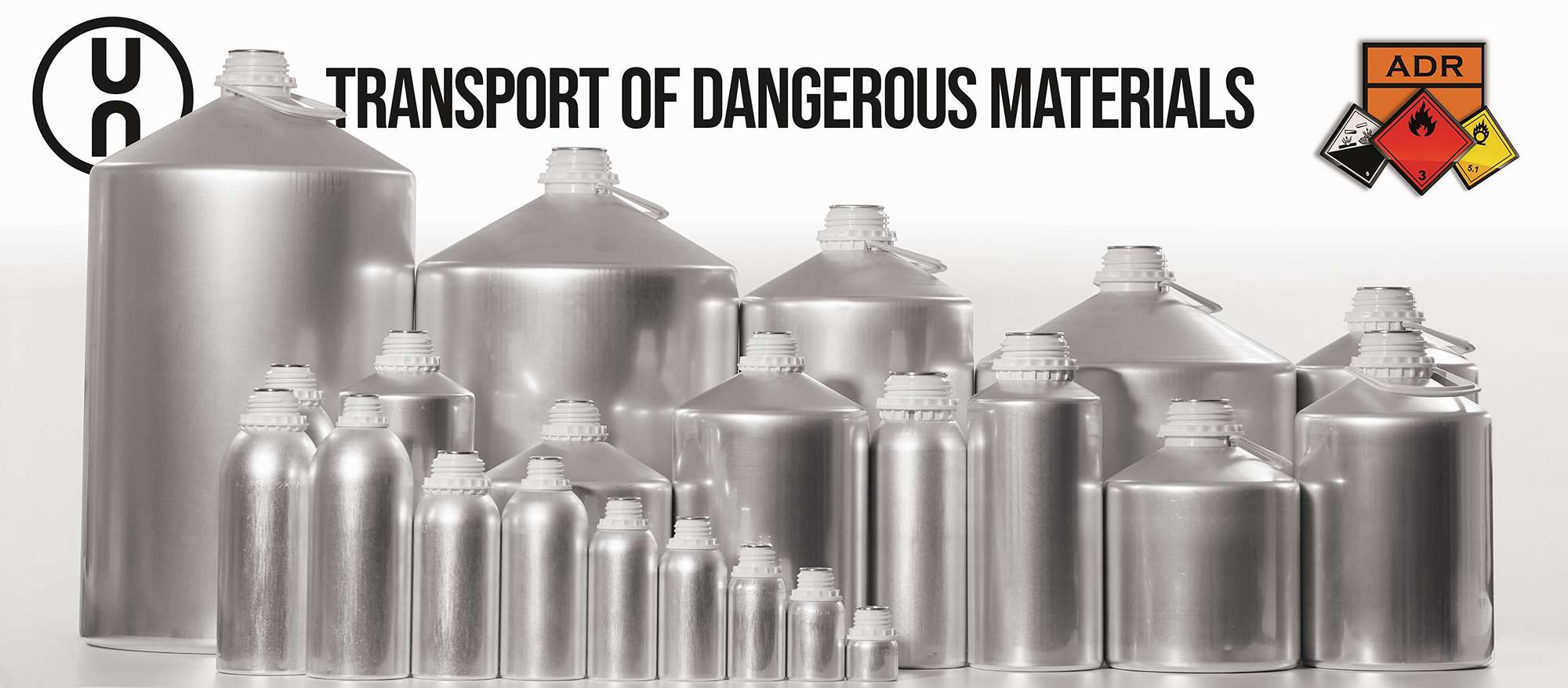

Manufacturers such as Tournaire have significant experience (since 1833 for Tournaire) in this sector and in-depth technical knowledge of the trades involved in transforming their materials (aluminium spinning and stamping for Tournaire). Manufacturers specialise in certain types of packaging or packaging materials or technology. This enables them to offer in-depth knowledge of containers and their performance, a wider range of approved products and the possibility of developing the container and approval to adapt it to your expectations. Tournaire, as a manufacturer of one-piece aluminium and multilayer plastic packaging, offers you a full and varied range of containers from 50 ml to 32 litres, approved either as ‘unitary’ or ‘combination’ (boxes). In addition to its over 180 years’ experience in the design and manufacture of industrial packaging and its ISO 9001 and 14001 certifications, Tournaire guarantees full compliance with the TDG regulatory constraints due to a high-performance quality organisation, audited at each of its sites at least every three years by approved laboratories and even more regularly by its customers.