Discover the news of the industrial group expert in the protection of sensitive and hazardous materials, as well as the list of trade shows and events in which Tournaire participates.

Service in the Packaging Industry: Beyond Product Supply

Introduction

Beyond the product...

Tournaire's vision of service in the packaging industry.

The packaging industry is more than just supplying products to customers. Service plays a key role in this sector. It encompasses a wide range of essential aspects that make a significant contribution to value creation, over and above the simple supply of a product.

Consulting and expertise

These days, companies live at a frenetic pace: developments multiply in order to constantly push new products onto ever-changing markets. The obligation to deliver results is essential if companies are to stay ahead of the game. Added to this are all the regulatory aspects they have to deal with, which can be extremely complex to master, particularly in terms of packaging. This is one area where companies have no room for error. These multiple constraints call for unfailing support in the choice and design of their products, and in particular their packaging. Today's packaging companies have evolved beyond simply selling standard products. They now offer personalized advice and technical expertise to meet the specific needs of each customer. This may include optimizing packaging materials, designing customized solutions, optimizing costs, or providing support on regulatory issues. Like Tournaire, some packaging companies have been established for many decades, and have a wealth of experience and know-how to offer their customers. Building on their past, these companies look to the future, continually imagining and developing new, tailor-made packaging solutions to meet their customers' most specific needs.  Each market, and each customer in particular, has its own particularities, and packaging companies strive to provide solutions tailored to them. Some sectors, such as pharmaceuticals, focus heavily on the total safety of materials to prevent any interaction with drugs. For aluminum packaging, this means a surface treatment called anodizing, which creates a layer of inert alumina to protect the packaged product. Although the range of packaged products is very broad, packaging companies have the necessary knowledge to guide customers towards appropriate solutions. Their experience enables them to offer solutions that are both economical and technically mature. They are a force to be reckoned with in key areas such as :

Each market, and each customer in particular, has its own particularities, and packaging companies strive to provide solutions tailored to them. Some sectors, such as pharmaceuticals, focus heavily on the total safety of materials to prevent any interaction with drugs. For aluminum packaging, this means a surface treatment called anodizing, which creates a layer of inert alumina to protect the packaged product. Although the range of packaged products is very broad, packaging companies have the necessary knowledge to guide customers towards appropriate solutions. Their experience enables them to offer solutions that are both economical and technically mature. They are a force to be reckoned with in key areas such as :

- - Material quality and resistance;

- The risk of interaction between the packaging and the packaged product, and possible solutions in terms of finishes (anodizing, varnish, etc.);

- General tightness, fine tightness and permeability (e.g. to oxygen or moisture absorption);

- Design and ergonomics.

In short, packaging companies offer their customers genuine know-how, combined with cutting-edge technical expertise, to meet today's challenges and propose solutions tailored to individual needs.

Speed and efficiency

In a context where trade has become globalized and competition no longer knows borders, companies need to implement effective strategies to remain competitive. The global supply chain, which begins with the raw material supplier and ends with the end customer, is a key point in this process, and one that could be described as sensitive. It is very quickly affected by the sometimes tense geopolitical context, by the vagaries of the weather in certain supply or transit regions, but also, as recently experienced, by a global epidemic such as COVID-19, which paralyzed the entire world. All the more so as, with a view to reducing capital costs, companies tend to limit their stock to the strict minimum. Management becomes tense and sometimes critical, particularly in the event of sharp variations in market demand.  When it comes to packaging, logistics play a decisive role. Companies strive to maintain high levels of flexibility and availability in production and inventory management, while optimizing the speed of deliveries. More generally, they are striving to increase the efficiency of all the processes that govern them. Indeed, the ability to respond quickly to requests and ensure on-time delivery contributes to the stability of customers' supply chains, and often helps to reinforce a competitive advantage. In this respect, some packaging companies such as Tournaire surpass packaging industry standards thanks to their great flexibility. Their production lines can be quickly equipped with specific tooling to switch from one packaging model to another. This agility makes it possible to produce small, specific batches and respond to any emergency situation. More generally, packaging production is optimized on the basis of annual sales forecasts, enabling a stock to be built up for the most common references. This stock helps to smooth production activity and maintain a high level of efficiency, while acting as a buffer in the event of last-minute customer demand. Efficiency and speed are also essential for order entry, usually carried out the same day by a multilingual team, as well as for parcel preparation and dispatch, whether by truck or container. To optimize logistics and offer a local service to their customers, companies work with a network of partners, agents and distributors throughout the world. In this way, the main packaging references are available immediately and in close proximity thanks to their partners' stocks, ranging from Brazil to China, via India and Australia. Logistics in all its forms is therefore a fundamental pillar of the packaging industry, guaranteeing flexibility, speed and efficiency. Thanks to their agility and global partnerships, packaging companies can respond to the specific needs of their customers and ensure punctual deliveries, thus contributing to the stability of the supply chain.

When it comes to packaging, logistics play a decisive role. Companies strive to maintain high levels of flexibility and availability in production and inventory management, while optimizing the speed of deliveries. More generally, they are striving to increase the efficiency of all the processes that govern them. Indeed, the ability to respond quickly to requests and ensure on-time delivery contributes to the stability of customers' supply chains, and often helps to reinforce a competitive advantage. In this respect, some packaging companies such as Tournaire surpass packaging industry standards thanks to their great flexibility. Their production lines can be quickly equipped with specific tooling to switch from one packaging model to another. This agility makes it possible to produce small, specific batches and respond to any emergency situation. More generally, packaging production is optimized on the basis of annual sales forecasts, enabling a stock to be built up for the most common references. This stock helps to smooth production activity and maintain a high level of efficiency, while acting as a buffer in the event of last-minute customer demand. Efficiency and speed are also essential for order entry, usually carried out the same day by a multilingual team, as well as for parcel preparation and dispatch, whether by truck or container. To optimize logistics and offer a local service to their customers, companies work with a network of partners, agents and distributors throughout the world. In this way, the main packaging references are available immediately and in close proximity thanks to their partners' stocks, ranging from Brazil to China, via India and Australia. Logistics in all its forms is therefore a fundamental pillar of the packaging industry, guaranteeing flexibility, speed and efficiency. Thanks to their agility and global partnerships, packaging companies can respond to the specific needs of their customers and ensure punctual deliveries, thus contributing to the stability of the supply chain.

Sustainability and environmental responsibility

To remain competitive, companies must adapt to the needs and concerns of consumers. The environment is now a major priority, with growing consumer expectations for more responsible business practices. As a result, governments are organizing themselves and strengthening their regulatory frameworks in terms of environmental responsibility, as well as health protection, putting even greater pressure on companies to integrate sustainable solutions that respect both the ecosystem and consumer health. In this context, companies in the packaging sector have a role to play. They are committed to sustainable development. They strive to offer eco-responsible packaging solutions while reducing their ecological footprint. They optimize their manufacturing processes, explore new avenues and deploy efficient recycling practices. This proactive approach responds to growing consumer demand and increasingly stringent regulations in the sector. In terms of environmental responsibility, the packaging industry is directly impacted by the new European Packaging and Packaging Waste Regulation (PPWR). This regulation reflects a more global and ambitious “3R” approach (Reduce, Reuse, Recycle) for household and industrial packaging. Coming into force in February 2025, the regulation aims to reduce packaging waste per person by 15% by 2040, compared with 2018 levels. To achieve this target, measures such as reducing unnecessary packaging, promoting reusable or refillable packaging, and improving the recyclability of materials are imposed. Packaging companies must therefore meet this challenge by implementing sustainable solutions, such as the use of recyclable materials like aluminum, which has the advantage of being infinitely recyclable, unlike other materials.  The use of recycled materials in the manufacture of finished products also represents a major challenge in terms of sustainability. This can be a tricky subject, as the composition of recycled materials is often subject to variations, however slight, which have a significant impact on the production of finished products. The packaging industry must therefore be agile in adapting its manufacturing processes to offer eco-responsible products. There are two main categories of recycled materials:

The use of recycled materials in the manufacture of finished products also represents a major challenge in terms of sustainability. This can be a tricky subject, as the composition of recycled materials is often subject to variations, however slight, which have a significant impact on the production of finished products. The packaging industry must therefore be agile in adapting its manufacturing processes to offer eco-responsible products. There are two main categories of recycled materials:

- PCR (Post-Consumer Recycling), which refers to recycled materials derived from post-consumer waste, such as packaging used on a daily basis.

- PIR (Post-Industrial Recycling), which refers to materials recycled directly from industrial waste generated during the manufacturing process, even before they reach the consumer.

Once recycled, these materials can be reintegrated into the production cycle. Industrial recycling thus maximizes resource efficiency and reduces the ecological footprint. Numerous other actions are implemented in all areas of the company to reduce its ecological footprint and offer its customers more environmentally-friendly products. These may include the use of renewable energies, the optimization of over-packaging, eco-responsible air-conditioning solutions, the provision of recharging points for electric vehicle, etc. Other environmental issues that have a direct impact on everyone's health are chemicals that have become controversial and are used for very specific applications, and for which substitution is complex. These include PFASs, used for their waterproofing and heat-resistance properties, etc., which are persistent in the environment because they degrade only very slowly. They also present a health risk as they accumulate in living organisms. Another example is BPA (bisphenol A), an endocrine disruptor used in the manufacture of certain plastics and resins. Because of their potential effects on the environment and health, the use of these products is restricted or even banned. Companies are striving to find alternatives to their use, with products that are more respectful of the environment and consumer health. In conclusion, the packaging industry is striving to meet growing expectations in terms of sustainable development and respect for the environment, as well as consumer health. Through optimized manufacturing practices, the use of recycled materials and compliance with new regulations, these companies can offer greener packaging solutions and reduce their ecological footprint. By meeting these challenges, they are helping to preserve our planet for future generations.

Technical Support and Training

Today, it has become crucial for companies to maintain a high level of product knowledge and expertise. Indeed, the globalization of markets and the challenges it poses in terms of competitiveness are driving companies to consolidate their knowledge and seek ever greater support from their partners. In the packaging sector, technical support and training are essential services that form an integral part of a company's offering. They provide their customers and partners with a whole range of educational documents to help them make the right packaging choices and expand their general knowledge of the sector. These documents can include practical fact sheets on various packaging-related topics, such as technical descriptions of the materials used, manufacturing processes, storage conditions, etc. With their concise format, these documents offer customers an overview of the essential points on the subject in question. Another very popular medium is FAQ (Frequently Asked Questions), which consist of a series of questions and answers covering a specific topic in a very pragmatic way. For example, Tournaire's packaging range for the pharmaceutical sector includes topics such as

- The type of material, its finish and its neutrality with the pharmaceutical compound;

- Quality control, chemical, particulate and biological cleanliness, and traceability;

- Packaging registration with the relevant authorities (EMA, FDA, CFDA, etc.) with a Drug Master File;

- Sterilization methods: DHS (Dry Heat Sterilization), autoclave, gamma radiation, etc.

Some companies go even further, offering training programs to optimize the use of their packaging, thus guaranteeing optimum performance. These days, digital technologies make it easier to deliver these programs, eliminating the need for face-to-face training. Many companies are opting for webinars, where the presence of a specialist speaker reinforces customer interest and commitment to the proposed solutions. Technical support for the packaging industry plays a key role in meeting environmental and legislative requirements. This subject, which is essential to the packaging industry, is constantly evolving and requires scrupulous monitoring. In addition to regulatory and environmental aspects, companies are able to support their customers on all the major issues of our time, demonstrating an expertise that goes far beyond the simple manufacture of packaging. In this respect, Tournaire, with its 192 years of experience, has established itself as a benchmark in its sector, both for the quality of its products and for the support it offers on the various aspects linked to its field of expertise. The packaging industry also provides technical support to its customers via its own laboratories. It can carry out a whole range of tests on behalf of its customers. For example, Tournaire is able to carry out fine leak testing for a particular product that the customer wishes to package, and which is highly volatile and/or toxic. It is therefore essential to ensure that the packaging is leak tight. Other types of tests, frequently carried out on behalf of customers, involve testing the durability and reliability of the packaging in the presence of the customer's own product. These so-called accelerated aging tests simulate the conditions to which packaging will be exposed during its life cycle, such as heat, humidity, etc., in the presence of the product. By accelerating these conditions, the tests make it possible to predict the lifespan of materials and identify possible failures before marketing. This ensures that products remain protected and packaging intact throughout their use, meeting the most stringent quality and safety requirements. By integrating technical support and training into its offering, the packaging sector is demonstrating its determination to support its customers far beyond the simple supply of products. By guaranteeing an in-depth understanding of materials and processes, and offering customized solutions, the industry boosts its customers' confidence and efficiency.

Accessories and equipment

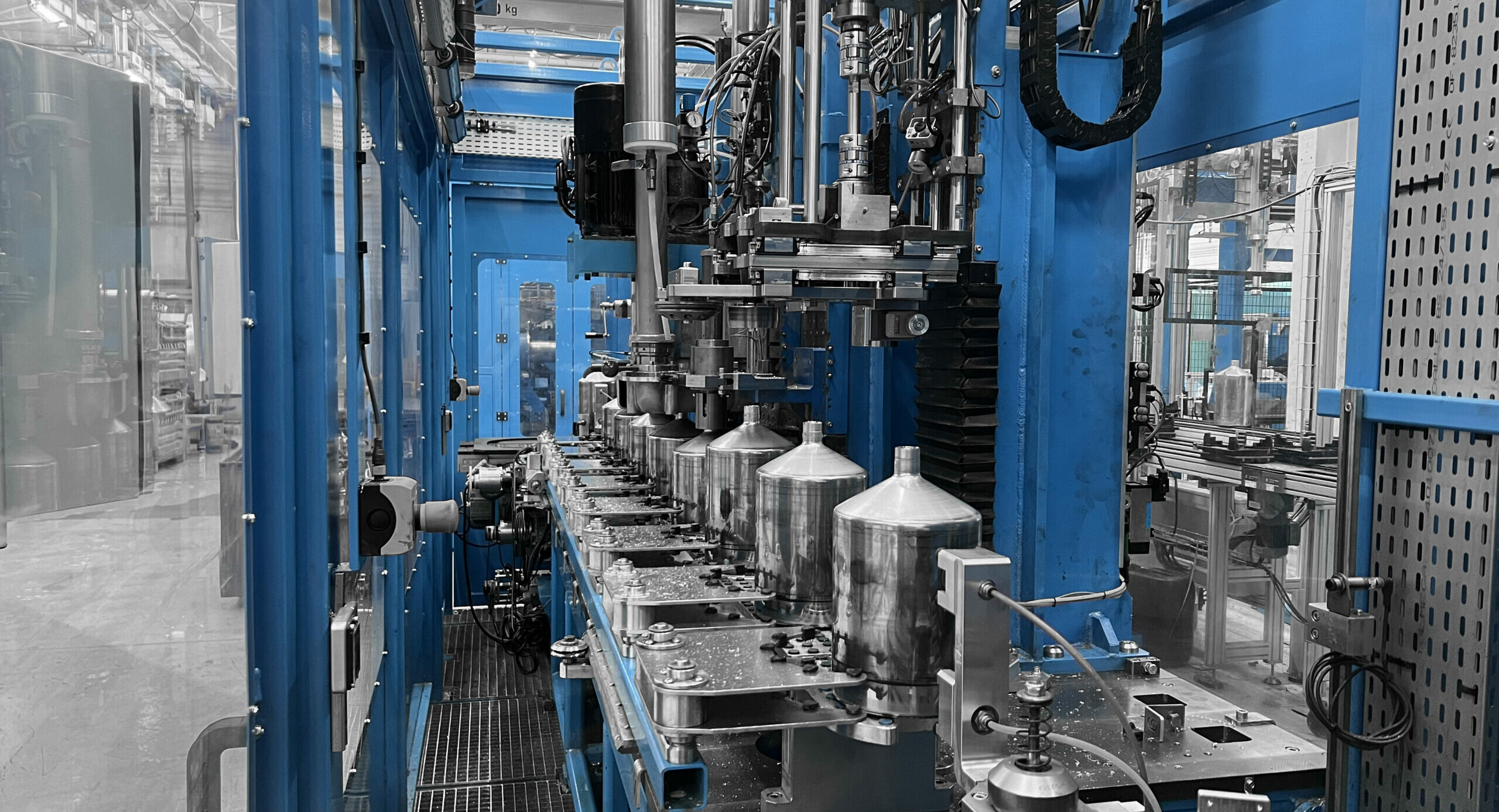

Alongside the products themselves, the packaging sector is able to adjust its offering to market trends thanks to modern equipment and a wide range of accessories. Packaging companies are constantly improving their manufacturing processes with state-of-the-art machinery, in order to anticipate their customers' needs. Accessories designed to optimize packaging use and make it more intuitive play a crucial role in safety, comfort and operating performance. Companies must constantly invest in advanced technologies and innovative accessories to meet the varied requirements of their customers. Constantly in tune with their markets, packaging companies strive to keep their production equipment in step with the most demanding industry standards. This translates into significant investment in cutting-edge technologies, enabling them, for example, to optimize pack loading and unloading processes at every stage of the manufacturing process. Another notable type of investment concerns lacquering equipment dedicated to certain types of packaging, enabling us to meet current regulations, for example in terms of food contact. They increase customization options to adapt to current trends, and ensure a very high and perfectly consistent level of quality. When it comes to the equipment installed on their customers' premises, packaging companies play a proactive role. In fact, during their use on the customer's premises, packaging goes through several essential stages, such as washing, sterilization, filling and sealing. These operations are crucial to guaranteeing the quality and safety of packaged products, and often require the use of industrial equipment. Thanks to strategic partnerships with specialized equipment designers, packaging companies offer their customers personalized support and sound advice in choosing the equipment best suited to their specific needs. As a pioneer in one-piece aluminum packaging, Tournaire stands out for its close collaboration with customers and their partners. This synergy is based on a dynamic exchange in which customers express their specific needs, while partners share their in-depth expertise as well as their knowledge of products, processes and markets. The result of this close collaboration is highly optimized solutions, offering concrete and lasting benefits to all parties involved. In addition to equipment, customer service is extended through the provision of a range of accessories. This includes, for example, ergonomic tools that assist with closure operations. In the industrial packaging sector, some of these accessories not only offer a better grip on closure systems, but are also used to ensure proper sealing, according to the torque specified by UN certification, when applicable. For other closure systems that require, for instance, the crimping of a cap onto a stopper—as is common in the pharmaceutical sector—a full set of accessories is available: suction-based systems for placing and removing the stopper, crimping pliers, de-capping tools, etc. These accessories enable customers to use the packaging under optimal conditions, ensuring both user safety and product integrity. Other innovative accessories are specifically designed for a customer’s particular use. These are often adapters that allow for quick and easy connection of the packaging to the customer’s available equipment.  As a result, packaging companies are constantly reinventing themselves to keep up with market trends and meet customer demands, by investing in state-of-the-art equipment and innovative accessories. This approach allows them to deliver optimal quality while ensuring the safety and ease of use of their packaging solutions. By staying attuned to market needs, they strengthen their competitiveness and ability to provide customized solutions.

As a result, packaging companies are constantly reinventing themselves to keep up with market trends and meet customer demands, by investing in state-of-the-art equipment and innovative accessories. This approach allows them to deliver optimal quality while ensuring the safety and ease of use of their packaging solutions. By staying attuned to market needs, they strengthen their competitiveness and ability to provide customized solutions.

Quality and Performance

Another key challenge for industries that use packaging is being able to rely on consistently exceptional quality, along with performance levels that exceed standard expectations, in order to meet growing market demands. Quality and performance are two of the most critical expectations of companies that rely on packaging. The packaging industry meets these expectations by ensuring traceability and implementing strict quality control procedures at every stage of production—from raw material supply to the finished product. This guarantees consistent quality and high performance for the customer, along with swift anomaly management to minimize production chain disruptions. Beyond full traceability from the aluminum raw material batch to the final packaging product batch, packaging companies conduct thorough quality checks on their production lines. These checks can be systematic and are often automated due to the industry’s high production speeds. For example, Tournaire's can production lines feature in-line air-tightness tests: each container passes under an automated system that tests the body’s seal using pressurized air to confirm its integrity. Additional checks are also carried out periodically or randomly to ensure smooth line operation. These tests may include wall thickness measurements at regular intervals, with some samples taken off the line for destructive testing. All results are recorded and stored, remaining accessible for future reference—especially in the event of a detected issue in a finished product batch. Cleanliness is a major quality concern, especially for packaging intended for food or pharmaceutical contact. These products undergo rigorous testing to guarantee impeccable cleanliness. In this regard, Tournaire has more than 20 years of data on packaging cleanliness, including:

- Particulate cleanliness

- Chemical cleanliness

- Microbiological cleanliness

This data is a valuable resource for enhancing Tournaire's expertise in packaging manufacturing and cleaning. Periodic testing may be performed directly on the production lines or in dedicated laboratories. Many packaging companies, including Tournaire, maintain in-house quality labs that oversee packaging functionality, contamination control, and sealing performance. These labs confirm product compliance with specifications and evaluate performance. They also conduct regulatory compliance testing, which is crucial in the packaging sector. For instance, most of the packaging manufactured by Tournaire is UN-certified, allowing for the safe transport of sensitive or hazardous materials under high safety standards defined by international regulations. Certification is granted following a series of tests conducted in-house and validated by an accredited organization.

- Today, ISO 9001 is the reference standard for quality assurance. Many packaging companies comply with this internationally recognized benchmark, highlighting their expertise and commitment. It also reflects their customer-centric culture and support for innovation. Quality is a key concern for these companies, which are frequently audited by their clients—particularly those in the demanding pharmaceutical sector. Packaging companies like Tournaire stand out not only for the performance of their products but also for the excellence-driven values they share with their customers.

Innovation and adaptability

Modern businesses face many challenges in staying aligned with market expectations. Among these, innovation and adaptability play a central role, providing the tools needed to respond to evolving consumer demands and comply with regulatory and environmental requirements. One of the main avenues for innovation is the development of new, eco-friendly materials. For example, biodegradable and compostable materials—such as plant-based bioplastics—offer sustainable alternatives to traditional plastics, which face significant recycling limitations. Other solutions include using endlessly recyclable and recycled materials such as aluminum, each with its own unique characteristics and challenges. In an ever-changing environment, anticipation, agility, and adaptability are essential for companies aiming to remain competitive in a highly dynamic industry. This is reflected in numerous patent filings, ensuring exclusivity and legal protection of innovations. This constant drive for innovation, combined with a deep understanding of emerging trends, enables the industry to deliver solutions that meet both functional and user experience expectations. Regulatory aspects also play a crucial role in this sector, often serving as a catalyst for innovation. Packaging companies must anticipate and adapt continuously to comply with current regulations. For instance, the Packaging and Packaging Waste Regulation (PPWR) in Europe imposes strict criteria for the reduction, reuse, and recycling of packaging. In response, companies are developing more efficient and less polluting production processes, and innovating with eco-responsible packaging solutions. Similar challenges exist regarding substances of concern like BPA and PFAS, with alternative solutions being developed to eliminate them while preserving essential packaging properties. Furthermore, some companies go beyond material and technological innovation by adopting customized approaches, designing packaging specifically tailored to customer needs. For example, personalized packaging solutions for pharmaceutical products highlight the industry’s adaptability to market demands. With typically long development and qualification timelines, a customer-centric approach—such as the one embraced by Tournaire—often results in highly effective packaging solutions. Thus, the packaging industry stands out through its continuous commitment to innovation and adaptability. This enables it to effectively tackle environmental and regulatory challenges while meeting the specific needs of customers. Thanks to these strengths, companies develop sustainable, customized solutions that boost their competitiveness in a constantly evolving sector and ensure greater customer satisfaction.

Conclusion

The packaging industry stands out for its comprehensive, personalized service that goes far beyond simply supplying products. Through expert advice and technical know-how, companies offer tailored solutions to meet the specific needs of each client. Innovation is at the heart of their business, allowing them to deliver increasingly modern, eco-responsible solutions aligned with new regulations. The development of accessories, along with technical support and training, ensures optimal packaging use, thereby increasing customer satisfaction and engagement. These companies also demonstrate great agility in ensuring flexible, efficient production, while maintaining a global supply chain through a network of partners. The quality and performance of their packaging are guaranteed by rigorous controls and full traceability. Thanks to this global and proactive approach, the packaging industry is well-positioned as a key player, ready to meet the challenges of today and tomorrow.

Glossary

- PFAS (Per- and Polyfluoroalkylated Substances): A group of over 10,000 chemical compounds containing at least one fully fluorinated carbon atom. They are used in many industries for their water-, oil- and heat-resistant properties.

- PPWR (Packaging and Packaging Waste Regulation): New European legislation on packaging and packaging waste. This regulation aims to harmonize and strengthen packaging requirements across the European Union.

- Recyclability: The ability of a material to be reused after processing to make new products, thereby reducing carbon footprints and the use of natural resources.

- Sustainability: The practice of using resources in a way that does not compromise the needs of future generations.

- Overpack: Additional packaging, often in the form of plastic film or cardboard, which is added to the primary packaging of one or more products.

- Ecological footprint: The ecological footprint is an indicator that evaluates the land and sea area required by a given population to meet its needs and absorb its waste.

- UN approval: UN is the symbol representing United Nations approval for hazardous substances.

- Traceability: The ability to identify a product's origin and trace its route from production to distribution.

- ISO 9001: Standard setting out the requirements for a quality management system.

Want to Know More? Contact the Tournaire Experts

Our guide has given you an overview of the latest developments in PFAS regulations as well as Tournaire's excellence in providing safe and innovative packaging solutions. If you would like to explore in more detail how our products and services can meet your specific needs, we are here to help.

Our experts are available for personalized consultations.

Visit our contact form to share your needs and questions with us. A member of our team will respond as quickly as possible to provide you with expert advice tailored to your industrial context. Tournaire is committed to providing not only high-quality products but also support and expertise that make a difference. Contact us today to move your project forward with a partner you can rely on.